Non-Destructive Testing Inspection Techniques & Equipments

Floormap 3D

Pipescan

Handscan

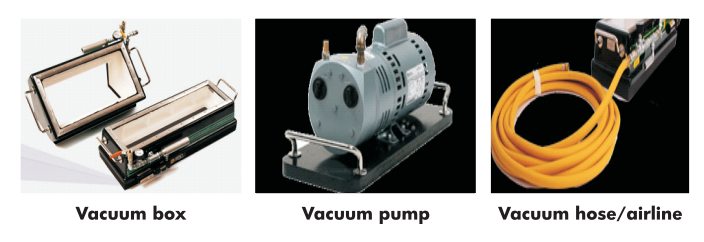

Vacuum Box

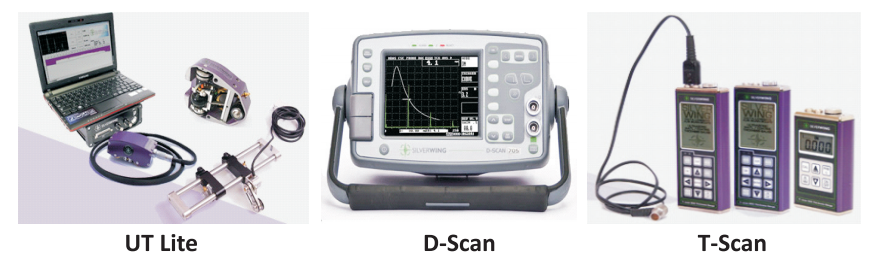

Ultrasonic Testing

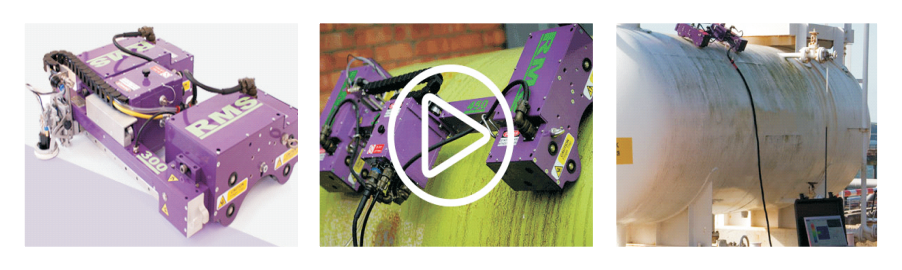

Scorpion

UT Lite

MPI

Guided Wave Long Range Ultrasonic